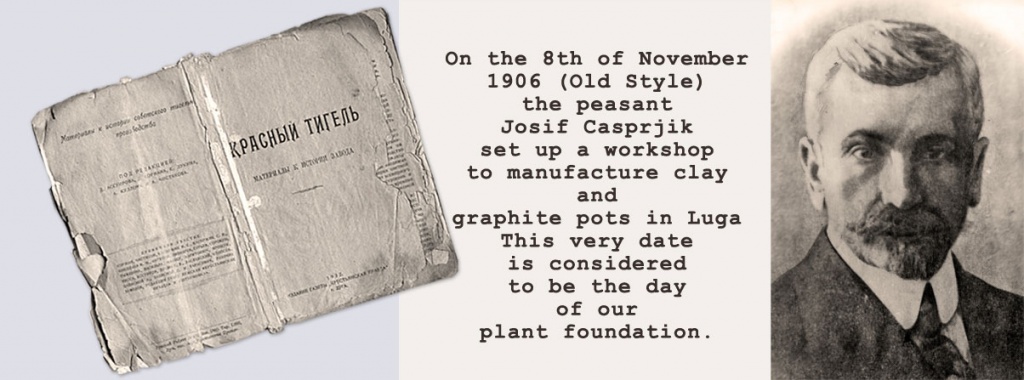

The plant went through many difficulties during the following years. In 1911 the private workshop ceased producing crucibles as it had not met competition and had not got governmental support. The further destiny of crucibles production is connected with restoration of industry and industrial development of the country. Because of the persistence and organizing abilities of the first head of Luga Integrated Industrial Plant D.A.Corman and technical talent of Josif Casprjik, the only one specialist in crucibles in the country of those days, our country got the native crucibles. This story became the plot of N.A.Brykin's book «The Provincial idea».

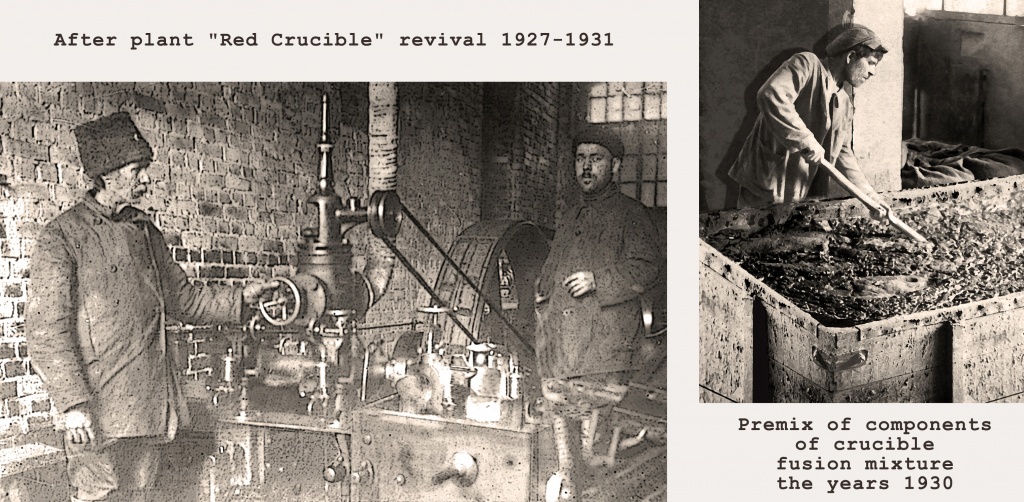

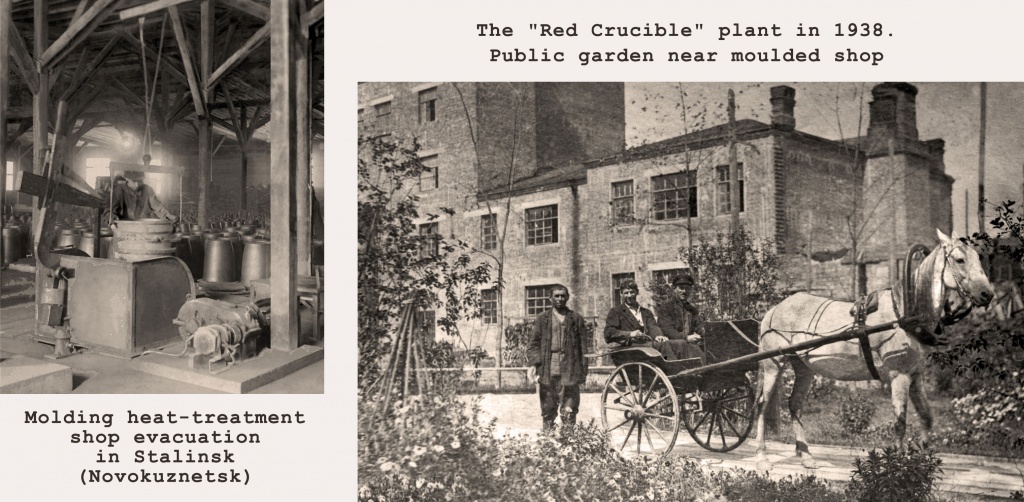

At this time the Integrated Plant started producing «grinding tools», and in 1926 the plant "Smychka" being the part of the Integrated Plant began producing abrasive tools on resinoid bond. These two plants were separate institutions until the Great Patriotic War. During the war the crucible plant "Red Crucible" producing crucibles was evacuated to Stalinsk of Kemerovo region and the plant "Smychka" was moved to Zlatoust. Later both plants were restored, expanded and united into one plant "Red Crucible" that began producing wheels on ceramic bond in 1957.

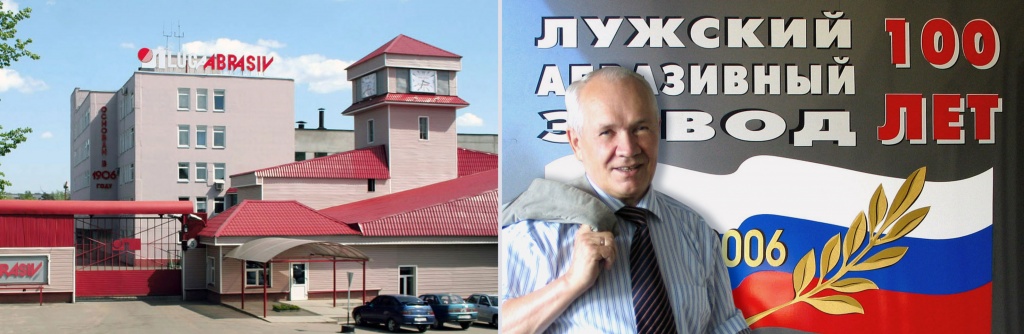

Gradually, Luga abrasive plant turned from an ordinary enterprise with a small range of products into a modern high-tech diversified manufacture producing the most diverse range of products (over 14 thousand standard sizes). All products of the plant are manufactured in Russia, at the production sites of Leningrad and Pskov regions. Arriving at the plant the consumer can purchase abrasive tools on resinoid and ceramic bonds, on flexible base, as well as crucibles and other graphite-containing products.

Luga abrasive plant has not only a glorious history, but also a present full of creative work. Due to the systematic policy pursued by the management aimed at improving the quality of products, increasing labor productivity, improving working conditions and production culture, in recent decades the plant has been carrying out large-scale work on reconstruction of production areas, modernization and renewal of equipment. The plant's specialists develop and implement innovative technologies with use of high-quality materials and components, including leading European companies. The result of the carried out work is the high quality and competitiveness of the Luga tools that is confirmed by the annual growth in demand for it not only from domestic consumers, but also from partners from the countries of near and far abroad.

The plant continues to develop dynamically, increases production volumes and renews the range of products paying great attention to their quality, approaches individually to the requirements of a particular customer. To meet the needs of buyers for high-quality domestic tools on a flexible base a new modern workshop for the production of coated abrasives was successfully launched at the industrial site of the plant in Luga in 2019.

Nowadays, JSC «Luga Abrasive Plant» is the world's largest separate enterprise for the production of abrasives, and «LUGAABRASIV» is a globally recognized trade mark and quality mark of Russian abrasive tools.