Abrasive tools must be stored in dry covered well-ventilated place with stable temperature within the limits of 15-20°C.

Organic bond wheels are perceptible to an alkaline condition and changes of temperature; thus they must not be stored together with chemicals and be subjected to unilateral heating. Keep away from heating devices. Grinding wheels are perceptible to strokes and flexural stresses.

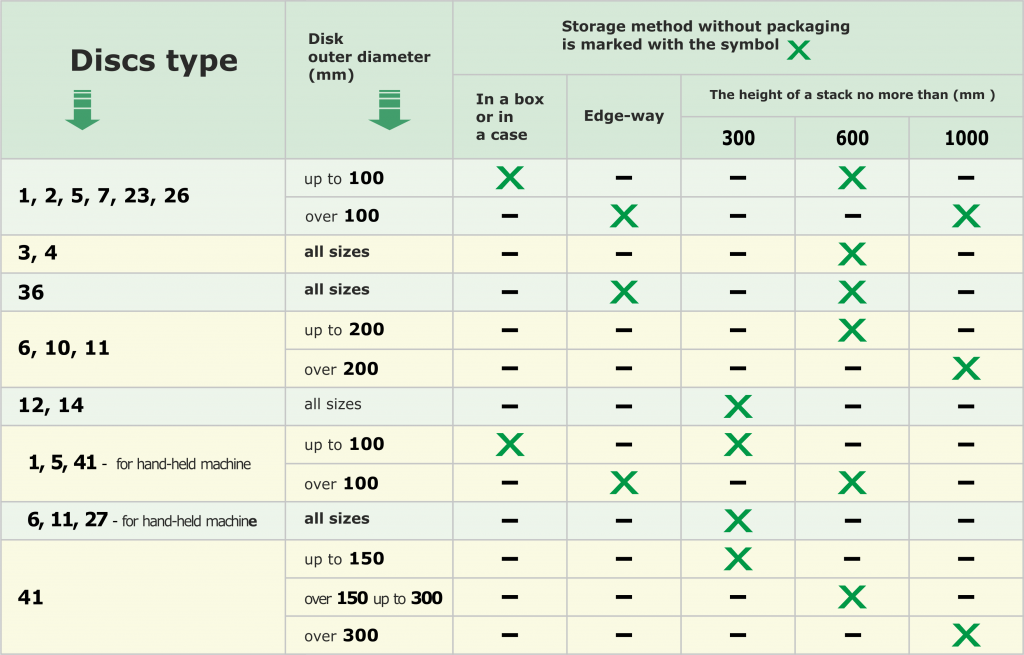

Storage methods of grinding and cutting wheels are specified in the table. Wheels can be stored in a transport packaging.

Grinding segments type 1С, 2С, ЗС ,5С, 6С width up to 150 mm and also.

Segments of the rest types should be kept in a stack no more than 600 mm.

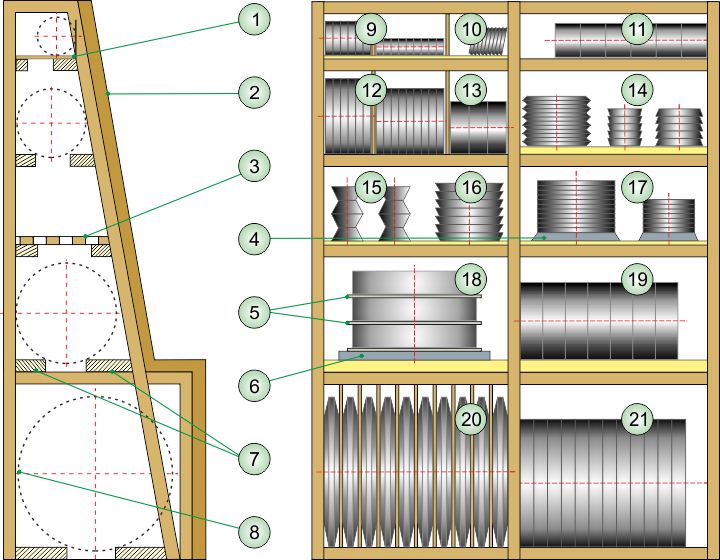

In the picture we have one of the versions of the right arrangement of abrasive tools on racks without consumer packaging depending on disks size.

Keep abrasives in dry nonfreezing places.

Recommended temperature of storage is 18-22°C at relative humidity of air 45-65%. Keep away from: heating devices, cold and damp walls, doors or windows. Don’t place directly on the floor. Keep away from direct sunlight.

Very careful storage of the abrasives during transportation is necessary.

Avoid mechanical damages, for example strokes, drops or bends. Then provide protection against precipitation, dew and hoar-frost.

Store the abrasive discs on flexible basis in their original packaging.

Once unpacked, the toll should be kept safely avoiding deformation. Open packaging of fiber disks only before use.

Coated abrasive rolls should be stacked dense rows in the longitudinal and transverse directions one-by-one. The height of the roll storage should not exceed 2 meters.

Tolls on Bakelite bond and flexible basis - Recommended keeping time is 3 (three) years.

Tools on flexible base - 5 (five) years

Tools on ceramic bond - have no expiration date.