OPERATION GUIDELINES OF THE CRUCIBLES

STORAGE

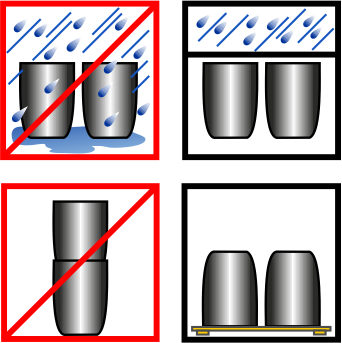

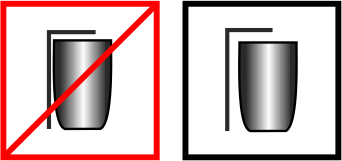

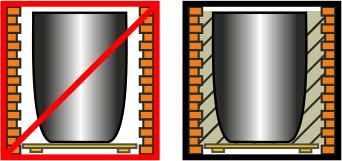

The crucibles should be stored in dry well-aired room, on wood shelving (supports).

The storage of the crucibles on concrete or metal floor is not allowed.

It is not allowed to put the crucibles one into another.

The storage of the crucibles on concrete or metal floor is not allowed.

It is not allowed to put the crucibles one into another.

TRANSPORTATION

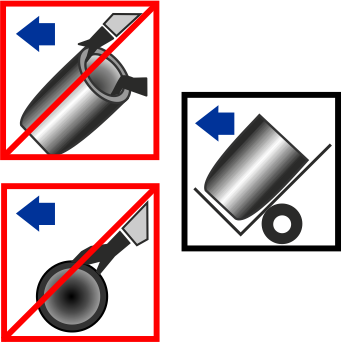

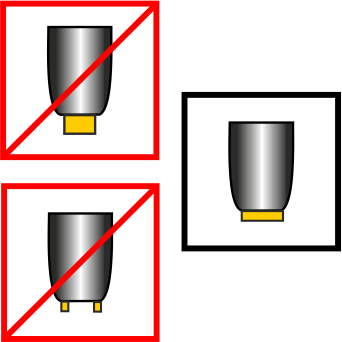

It is impossible to enable pushes and impacts on the crucibles.

It is impossible tо move the crucibles on a floor edgewise or on the bottom edge.

It is recommended to use the trolleys with padding for transportation.

It is impossible tо move the crucibles on a floor edgewise or on the bottom edge.

It is recommended to use the trolleys with padding for transportation.

PREPARATION OF CRUCIBLES

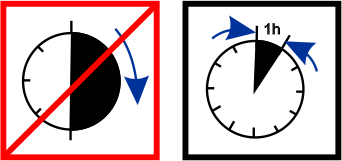

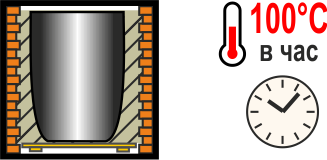

Drying of crucibles

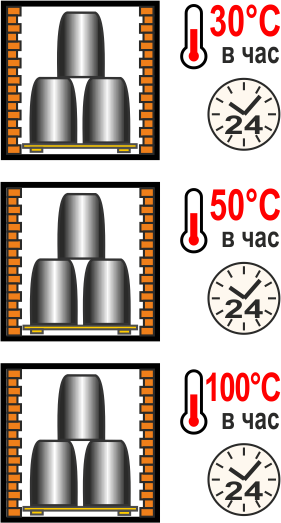

- at temperature 200°C 24 hours at least.

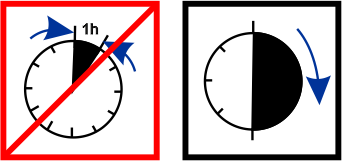

The rise of temperature should not be sudden at most 30°C per hour. Glowing of crucibles

- crucibles of type C - rise of temperature till 900°C in 50°C per hour.

- crucibles of type A and K - rise of temperature till 1050°C in 100°C per hour.

- crucibles of type X - rise of temperature till 400°C in 100°C per hour and further till 1050°C as soon as possible.

- at temperature 200°C 24 hours at least.

The rise of temperature should not be sudden at most 30°C per hour. Glowing of crucibles

- crucibles of type C - rise of temperature till 900°C in 50°C per hour.

- crucibles of type A and K - rise of temperature till 1050°C in 100°C per hour.

- crucibles of type X - rise of temperature till 400°C in 100°C per hour and further till 1050°C as soon as possible.

INSTALLATION OF THE CRUCIBLES

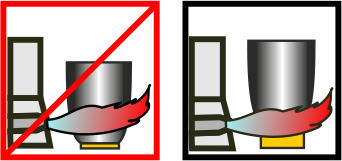

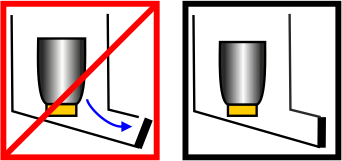

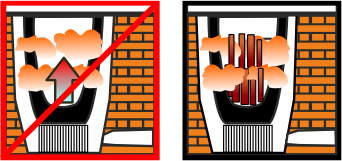

The burner axis should be in a bottom plane of a crucible.

The burner should be established so that the flame does not flap directly in a crucible and bent it on tangent.

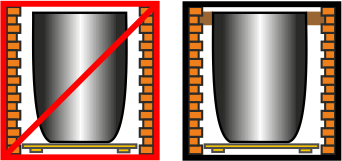

A gap between a crucible and a furnace cover should be insulated by thermoinsulating material.

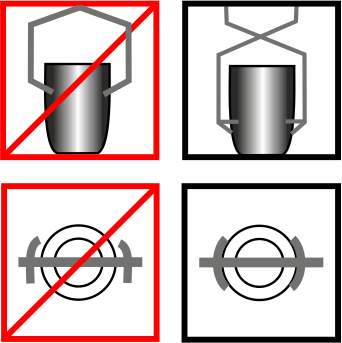

Use only standard supports. Between crucible and support should be separating material: paper, coke, alumina.

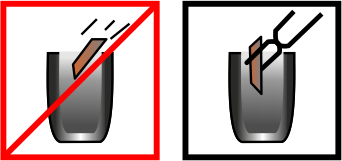

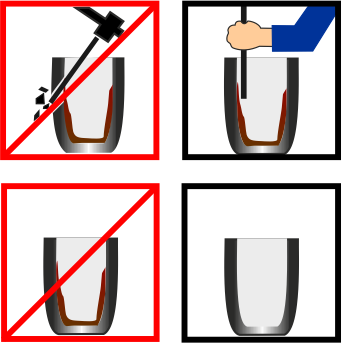

For installation and extraction of crucibles tongs (claws) should be used. Tongs should correspond to the shape of crucible and be wrapped up with mild material.

In resistance ovens and induction furnaces air gap between crucible's edge and oven's cover should be sealed up by mixture on the ground of fireproof clay.

In resistance ovens and induction furnaces air gap between crucible's edge and oven's cover should be sealed up by mixture on the ground of fireproof clay.

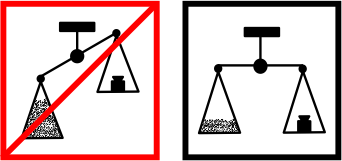

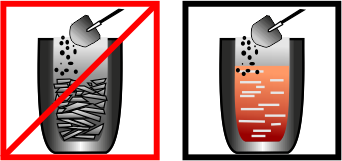

LOADING OF METAL

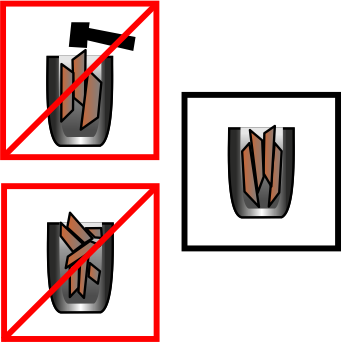

The metal is necessary to load in the previously warmed-over crucible. The metal should be dry and heated a little. The large pieces should be placed into crucible by grips, avoiding their impacts with a crucible.

The ingots of metal should be packed into a crucible upright excluding jamming of separate pieces.

CONDUCTION OF MELTING

It is forbidden categorically to warm up a crucible with metal stiffened in it. The hole for emergency output of molten metal in furnace should be closed.

Metal melting is necessary to conduct as soon as possible.

Don't leave empty crucible in the furnace between meltings. Period between meltings should be minimal.

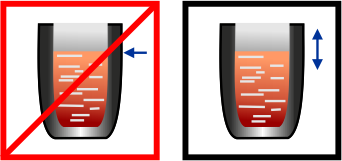

It is necessary to change a level of melt in a crucible in order to avoid fretting of crucible walls by drosses on a “mirror” of metal.

Keep strictly to necessary quantity of chemical components for modification of alloys.

Enter the components only into molten metal.

After breaks in work (e.g. stops during weekends) it is necessary to warm up slowly the empty crucibles in the furnace regardless of its type.

In induction furnaces where heating and metal fusion occur at the expense of currents proceeding in it, and the crucible is heated from metal, it is recommended to increase gradually the energy to provide uniform heating of the crucible. The optimum decision in this case is the continuous operating mode.

CLEANING OF THE CRUCIBLES

At disconnection of the furnace it is necessary to remove the fluid melt from crucible. At the end of melting process the drosses should be accurately cleaned off from an internal surface of an hot crucible with the help of the metal scraper or blade

Efficient use of the crucibles means the correct choice of the crucible mark. This task is quite difficult and solution in mark crucible choice depends on terms of exploitation in each specific situation.