11

Fe

S

Cl

T

H

D

400

400

400

400

400

200

125

125

1.0

0.8

A 54 S BF

A 60 S BF

12250

12250

12250

12250

12250

12250

0.026

0.019

125

125

1.6

1.8

A 40 S BF

A 40 S BF

0.041

0.047

125 1.2

A 54 S BF

0.030

125 1.4

A 40 S BF

0.036

22.23

22.23

22.23; 32

22.23; 32

22.23; 32

22.23; 32

150

150

1.4

1.2

A 40 S BF

A 54 S BF

0.054

0.045

200

200

22.23; 32

22.23; 32

150

150

1.6

1.8

A 40 S BF

A 40 S BF

0.060

0.068

200

200

180

180

180

1.6

1.8

1.4

A 40 S BF

A 40 S BF

A 40 S BF

8500

8500

8500

0.087

0.098

0.077

150

150

200

200

230

230

1.6

1.6

1.8

A 40 S BF

A 40 S BF

A 40 S BF

7650

6650

6650

0.108

0.143

0.161

100

100

100

22.23; 32

22.23; 32

22.23; 32

16;22.23; 32

16;22.23; 32

22.23; 32

22.23; 32

22.23; 32

150 1.0

A 54 S BF

10200

10200

10200

10200

10200

0.037

200

22.23; 32

200 1.8

A 40 S BF

7650

0.122

100

22.23; 32

N v lty

o e

!

Nov lty!

e

Nov lty!

e

y

Novelt !

N v lty

o e

!

METAL+INOX

Special structure of the wheels, which don`t contain

iron, sulphur and chlorine allows to avoid “cauterizations”

of cut up and protected material and its soiling during

the process of working.

For high-performance cutting the details and constructions made of different kinds of steels

and high speed steels. Especially effective during cutting slender profile and

sheet metal.

80m/s

The plant receives the orders of wheels manufacturing with dimensions and characteristics

not indicated in the given table.

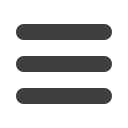

Type 41

D,

mm

Working speed,

RPM

T,

mm

Characteristic

Weight,

kg

H,

mm