50

20

63

20

80

20

100

20

100

20

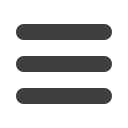

D

H

T

44

80

20

125

32

125

32

125

32

150

150

32

32

150

32

150

32

150

32

150

32

150

32

150

150

32

32

175

32

175

32

175

175

32

32

200

32

200

32

200

32

200

32

200

32

125

32

125

40

20

20

10

20

100

20

25

50

8

6

10

16

20

25

32

50

100

13

20

25

32

10

16

20

25

32

16

90

50

C 30 O B

C 24 Q B

C 24 Q B

C 40 Q B

C 24 P B

C 24 Q B

C 24 P B

C 24 Q B

C 16 P B

C 24 Q B

C 24 Q B

C 24 Q B

C 24 O B

C 20 Q B

C 16 Q B

C 24 Q B

C 24 Q B

C 24 Q B

C 30 P B

C 24 P B

C 24 P B

C 24 P B

C 40 O B

C 40 P B

C 24 P B

C 24 Q B

C 16 Q B

C 24 P B

C 20 Н B

0.180 32

0.126

50

0.223

20

0.170

64

0.357

32

1.116

4

0.543

24

0.679

16

1.358

8

0.283

0.212

40

40

0.354

32

0.586

20

0.708

16

0.998

12

1.278

8

2.014

3.994

8

4

0.634

20

0.975

12

1.219

1.762

10

8

0.642

16

1.027

10

1.450

8

1.673

6

2.140

4

0.426

32

15300

12150

9550

7650

76 05

9550

6150

6150

6150

5100

5100

5100

5100

5100

5100

5100

5100

5100

4360

4360

4360

4360

3850

3850

3850

3850

3850

6150

6150 1.914

8

STONE

For high-performance smoothing of natural and

artificial stone, fire-brick and other mineral materials.

The plant receives the orders of wheels manufacturing with dimensions and characteristics

not indicated in the given table.

Type 1

40m/s

D,

mm

Working speed,

RPM

T,

mm

Characteristic

Weight,

kg

H,

mm