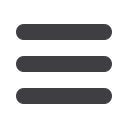

D,

mm

H,

mm

mm

d,

d

D

H

223

80

80

80

80

80

80

80

80

80

30

30

30

30

30

30

30

30

30

8; 12

8; 12

8; 12

8; 12

8; 12

8; 12

8; 12

8; 12

8; 12

50

50

50

50

50

50

50

50

50

9550

9550

9550

9550

9550

9550

9550

9550

9550

A 40

A 36

A 50

A 60

A 80

A 100

A 120

A 150

A 180

80

80

80

30

30

30

8; 12

8; 12

8; 12

50

50

50

9550

9550

9550

A 240

A 320

A 220

60

60

60

60

60

60

60

60

40

40

40

40

40

40

40

40

8; 12

8; 12

8; 12

8; 12

8; 12

8; 12

8; 12

8; 12

50

50

50

50

50

50

50

50

12730

12730

12730

12730

12730

12730

12730

12730

A 80

A 240

A 320

A 100

A 120

A 150

A 180

A 220

80

80

8; 12

8; 12

50

50

50

50

9550

9550

A 100

A 120

80

80

40

40

40

40

8; 12

8; 12

9550

9550

A 60

A 80

50

50

80

80

40

40

8; 12

8; 12

9550

9550

A 40

A 50

The plant receives the orders of wheels manufacturing with dimensions and characteristics

not indicated in the given table.

Type KL

Used for draft, intermediate and final grinding of different metals, plastic, wood, coloured

and lacquered surfaces, putty. Grinding wheels are well tuned up to the profile of the

processed blank and guarantee even nature of the grinding surface up to full wearing

of the wheel.

40m/s

Working speed,

RPM

Characteristic