35

m

/

s

D,

mm

T,

mm

H,

mm

The plant receives the orders of wheels manufacturing with dimensions and characteristics

not indicated in the given table.

P,

mm

F,

mm

For flat, round inner grinding the details and

constructions made of different types of steels,

for sharpening the cutting tools made of high

speed steels.

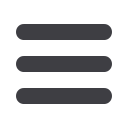

D

P

H

T

F

153

20

13

32

40

25

32

20

20

16

25

20

20

50

40

60

50

40

40

40

30

48

35

32

32

0.061

0.158

0.372

0.356

0.380

0.405

0.271

0.205

64

16

16

16

16

8

13400

8790

7340

6700

6700

6700

6700

40

65

50

70

48

75

80

80

50

76

80

80

80

91

100

100

13

0.033

20

36

16750

25

32

40

20

32

0.205

8400

8400

8400

8400

40

65

80

20

40

0.349

50

86

100

20

30

0.420

50

50

100

32

32; 51; 76

32

50

63

50

38

50

38

32

65

25.4

50

63

80

38

38

55

0.969

0.824

0.582

0.822

1.642

2.174

8

8

8

8

4

4

5350

5350

5350

4500

4500

4500

4500

4500

85

100

107

130

100

100

125

125

125

150

150

150

63.5

50

35

0.869

8

125

150

51

32

0.957

8

5850

63

76

114

25.4

50

2.064

4

75

100

150

20

40

32

0.147

36

36

36

36

36

36

11150

42

60

32

70

55

1.217

4

4500

125

150

Type 6

GRINDING WHEELS - CYLINDRICAL CUPS

Working speed,

RPM

Weight,

kg

y

Novelt !

A; WA

F180-F22

6-8

1; 2

F-Q

АA; A

Characteristic

Grit

Hardness

Material

Structure

Accuracy class

Unbalance class