38

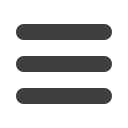

T

H

D

22.23; 32

22.23; 32

22.23; 32

22.23; 32

230

230

230

230

2.0

2.5

3.0

4.0

22.23; 32

230 2.3

22.23; 32

22.23; 32

16; 22.23; 32

16; 22.23

22.23

180

180

180

180

180

1.6

1.8

2.0

2.5

3.0

22.23; 32

180 4.0

22.23; 32

180 2.3

22.23

180 1.4

22.23; 32

22.23; 32

230

230

1.8

1.6

22.23; 32

22.23; 32

22.23; 32

22.23; 32

22.23; 32

200

200

200

200

200

200

2.0

1.6

1.8

2.5

3.0

4.0 22.23; 32

22.23; 32

200 2.3

C 36 R BF

C 30 R BF

C 24 R BF

C 24 R BF

C 30 R BF

C 40 R BF

C 36 R BF

C 36 R BF

C 30 R BF

C 24 R BF

C 24 R BF

C 30 R BF

C 40 R BF

C 36 R BF

C 40 R BF

C

C

C

36

40

36

R

R

R

BF

BF

BF

C 30 R BF

C 24 R BF

C 24 R BF

C 30 R BF

50

50

50

6650

6650

6650

6650

0.166

0.208

0.250

0.333

40

50

6650 0.191

150

150

150

100

50

8500

8500

8500

8500

8500

0.082

0.091

0.101

0.126

0.152

60

8500 0,203

100

8500 0.116

200

8500 0.071

100

100

6650

6650

0.150

0.133

50

100

100

50

50

7650

7650

7650

7650

7650

7650

0.125

0.100

0.112

0156

0,188

0.257 40

50

7650 0.144

D,

mm

Working speed,

RPM

T,

mm

Characteristic

Weight,

kg

H,

mm

STONE AND CONCRETE

The plant receives the orders of wheels manufacturing with dimensions and characteristics

not indicated in the given table.

Type 41

80m/s

For high-performance cutting of natural and

artificial stone, fire-brick and concrete articles.

Novelty!

lty

Nove

!

Novelty!

Novelty!

N v lty

o e

!