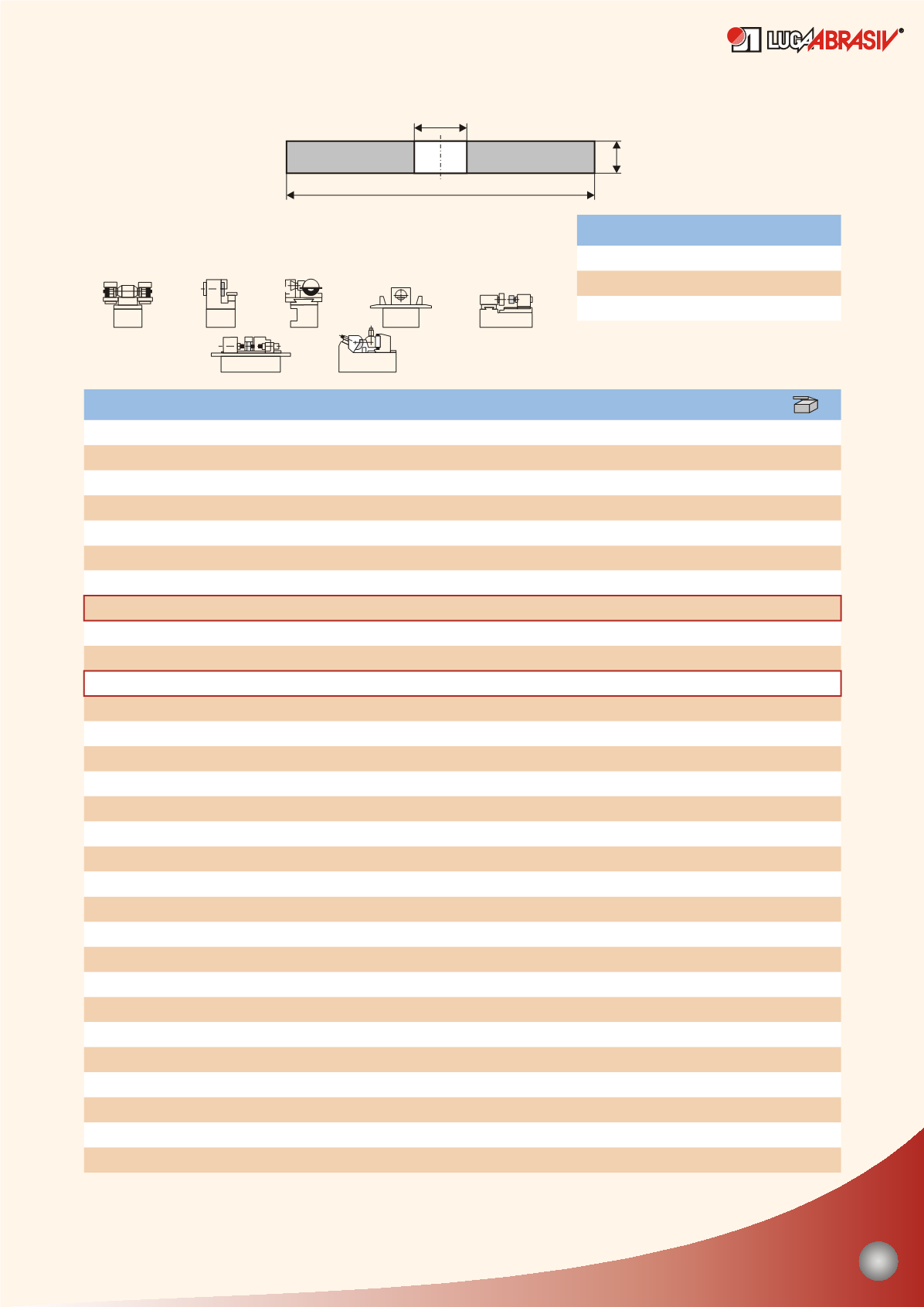

D

H

T

T,

mm

D,

mm

H,

mm

72

STEEL

F100-F12

I-T

16

20

25

32

40

200

200

200

200

200

2.747

2.546

1.955

1.434

1.148

4

4

6

8

10

3850

3850

3850

3850

3850

6

8

10

13

16

20

25

32

40

63

100

6

8

10

13

250

250

250

250

250

250

250

250

250

250

250

300

300

300

300

0.920

1.296

1.620

1.994

10.438

7.160

4.935

3.620

2.798

2.239

1.848

1.455

1.155

0.905

0.679

9

7

9

15

2

2

4

4

6

8

4

12

14

20

3100

3100

3100

3100

3100

3100

3100

3100

3100

3100

3100

2550

2550

2550

2550

16

300

2.175

6

2550

13

255

1.454

5

3000

50

250

6.170

2

2

3100

100

38

40

70

80

200

200

200

230

230

2.968

3.158

6.298

5.570

5.738

4

4

1

2

2

3850

3850

3850

3350

3350

63

200

4.326

2

3850

13

200

32; 76

32; 76

76

32

32

32; 76

32; 76

32; 76

32; 76

32; 76

32; 76

32; 76

32; 76

76; 127

32; 76; 127

32; 76; 127

32; 76; 127

76; 127

32; 76

76

127

60

32; 76

100

76; 100

76

32

32

76

32

0.932

12

3850

The plant receives the orders of wheels manufacturing with dimensions and characteristics

not indicated in the given table.

Type 1

Intended for all types of grinding and snagging

operations the details and constructions made of

different kinds of steels, sharpening of cutting tools.

A; WA

Grit

Hardness

Material

Characteristic

Working speed,

RPM

Weight,

kg

lty

Nove

!

N v lty

o e

!

4

0m/s