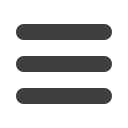

D

H

T

T,

mm

D,

mm

H,

mm

50

40

20

16

100

80

63

50

40

32

20

10

150

125

100

50

40

32

25

20

160

350

350

350

350

350

350

350

350

400

400

400

400

400

400

400

400

450

450

450

450

300

127; 203

127; 203

127; 203

127; 203

127; 203

127; 203

76; 127; 203

203

203

203

203

203

127

127

203

203

203

203

203

127

127

16.183

13.574

6.790

5.430

23.840

19.070

15.018

13.237

11.749

9.239

5.774

2.089

23.212

19.092

16.313

9.684

9.532

4.736

3.700

4.269

22.207

3

3

2

2

1

1

1

6

3

3

2

1

1

1

1

2

2

1

1

4

1

2200

2200

2200

2200

2200

2200

2200

2200

1950

1950

1950

1950

1950

1950

1950

1950

1700

1700

1700

1700

2550

40

32

80

63

500

500

450

450

203

203

203

203

16.760

13.408

23.494

18.698

2

2

1

1

1550

1550

1700

1700

STEEL

73

150

300

127

20.819

1

2550

40

32

300

300

76; 127

32; 76; 127

6.878

5.502

2

2

2550

2550

F100-F12

I-T

25

300

32; 76

3.830

3

2550

20

300

32; 76

3.007

4

2550

The plant receives the orders of wheels manufacturing with dimensions and characteristics

not indicated in the given table.

Type 1

Intended for all types of grinding and snagging

operations the details and constructions made of

different kinds of steels, sharpening of cutting tools.

Characteristic

A; WA

Grit

Hardness

Material

Working speed,

RPM

Weight,

kg

4

0m/s