For tooth-grinding, thread-grinding the details made

of different types of steels, sharpening of cutting

tools made of high speed steels.

50

m

/

s

D,

mm

250

250

250

250

300

300

300

1.000

1.260

1.500

1.790

2.400

2.890

3.080

5

10

8

6

3

3

3

3850

3850

3850

3850

3850

3200

3200

3200

T,

mm

10

13

16

20

20

25

25

40

40

40

40

40

40

60

a

H,

mm

76; 127

76

76

76

127

127

127

The plant receives the orders of wheels manufacturing with dimensions and characteristics

not indicated in the given table.

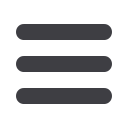

D

H

T

a

146

350

350

350

350

350

400

400

400

400

400

1.360

2.930

3.380

4.240

5.330

1.670

2.060

4.910

5.870

7.110

9

4

4

3

2

7

6

3

2

2

2750

2750

2750

2750

2750

2400

2400

2400

2400

2400

2400

2400

8

16

20

25

32

8

10

20

25

32

60

40

40

40

40

60

60

40

40

40

127; 203

160

127

127

127

127

203

203

127

127

400

7.580

2

36

60

127

400

2.726

6

13

60

203

250

2.030

4

25

40

76

300

4.167

2

3200

32

60

76

350

4.186

3

2750

2400

25

40

90

400

450

8.087

8.841

2

2

2150

40

32

60

60

127

127

DOUBLE-SIDED CONIC-PROFILE

GRINDING WHEELS

Type 4

Working speed,

RPM

Weight,

kg

Novelty!

N v lty

o e

!

lty

Nove

!

Novelty!

WA

F180-F36

4-7

1; 2

J-P

АA; A

Characteristic

Grit

Hardness

Material

Structure

Accuracy class

Unbalance class