143

50

m

/

s

For sharpening of rip- and disc-saws teeth made

of instrumental tools, spline-grinding, tooth-grinding,

sharpening operations with cutting tools made

of high speed steels.

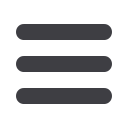

H

T

D

a

D,

mm

T,

mm

H,

mm

65

0.088

80

0.048

80

0.070

80

0.098

8

20

20

20

83

20

30

35

108

99

81

63

14600

12000

12000

12000

The plant receives the orders of wheels manufacturing with dimensions and characteristics

not indicated in the given table.

12

8

10

13

a

,

°

100

0.109

125

0.140

125

0.170

125

150

150

150

150

150

150

175

175

175

180

200

200

200

200

20

32

32

32

20

32

32

32

32

32

32

32

32

32

32

32

32; 51

32; 51

20

10

25

30

45

10

35

20

25

18

10

60

20

30

45

10

10

25

0.350

0.220

0.220

0.340

0.400

0.420

0.550

0.360

0.635

0.780

2.060

0.336

0.500

0.600

0.890

80

64

64

32

40

36

28

20

20

16

22

20

8

4

20

16

12

10

9550

9550

7650

7650

7650

6400

6400

6400

6400

6400

6400

5450

5450

5450

5350

4800

4800

4800

4800

8

8

10

16

6

8

10

13

16

20

10

13

16

60

8

10

13

16

100

20

30

0.134

64

10

0.073

10

96

100

20

9550

6

250

32; 76

45

0.644

12

3850

6

200

32; 51

30

0.850

8

4800

20

Working speed,

RPM

Weight,

kg

A

F180-F36

4-7

1; 2

J-Q

АA; A

Characteristic

Grit

Hardness

Material

Structure

Accuracy class

Unbalance class

w

Type 3