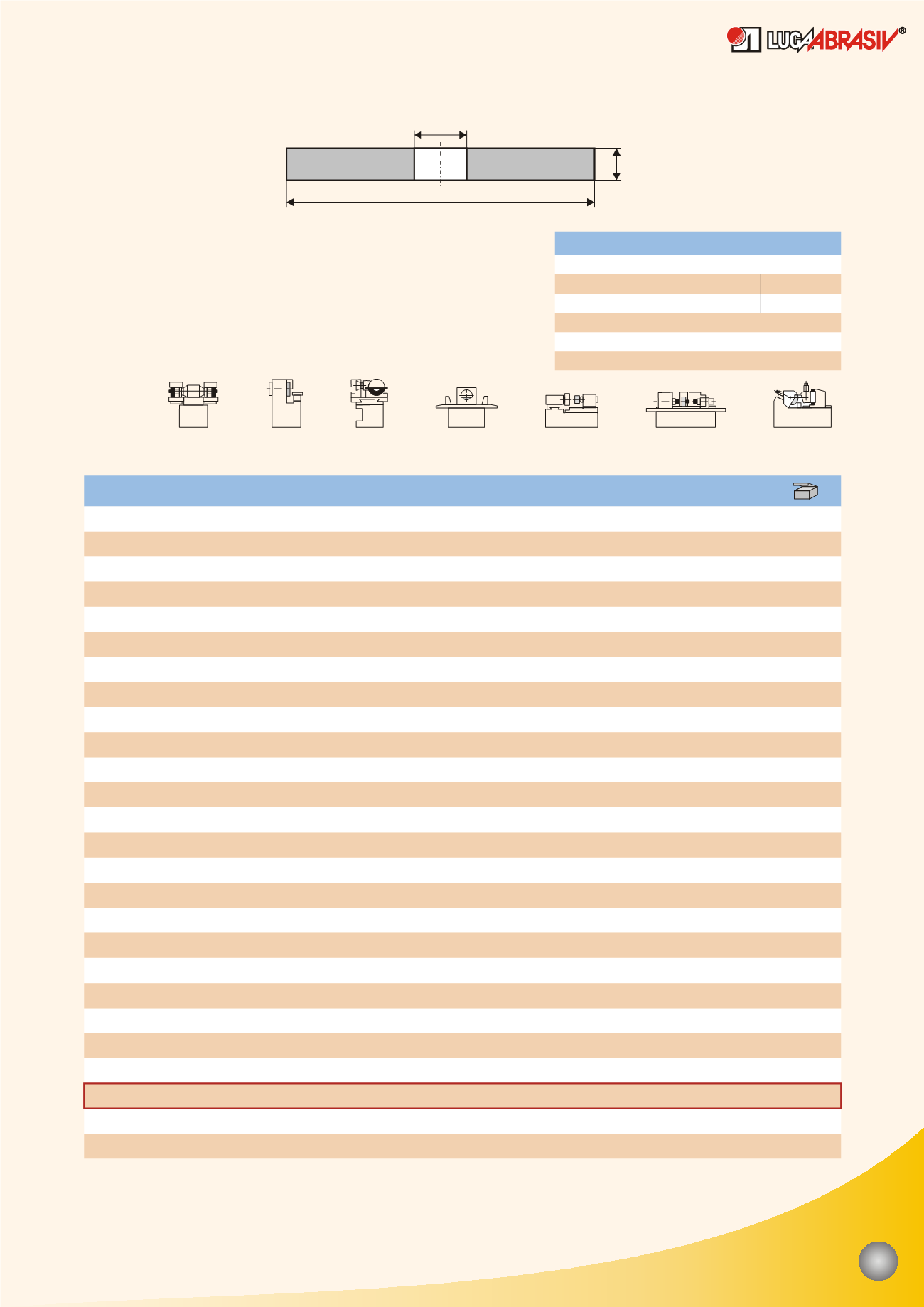

T,

mm

D,

mm

H,

mm

W

А

D

H

T

118

50

m

/

s

8

6

4

100

80

63

50

80

80

80

80

100

100

100

20; 32; 40

20; 32

20; 32

20

20

20; 32

20

0.137

0.105

0.072

1.090

0.855

0.674

0.535

80

96

160

4

9

4

18

9550

9550

9550

9550

9550

9550

9550

9550

9550

9550

9550

9550

9550

9550

10

13

100

100

20; 32

20; 32

0.171

0.223

64

48

32

25

20

16

100

100

100

100

20; 32

20; 32

20; 32

20; 32

0.537

0.429

0.343

0.274

16

24

32

40

100

80

100

100

20

20; 32

1.711

1.370

8

8

50

40

100

100

20; 32

20; 32

0.839

0.671

16

16

63

100

20; 32

1.078

8

40

32

80

80

20

20

0.415

0.332

8

27

12000

12000

12000

12000

12000

12000

32

40

50

90

90

90

20

20

20

0.416

0.520

0.665

10610

10610

10610

16

12

12

8

110

51

0.131

40

8680

16

108

45

0.267

8800

35

110

20

0.705

8680

20

8

The plant receives the orders of wheels manufacturing with dimensions and characteristics

not indicated in the given table.

For all types of grinding the details and constructions

of different kinds of steels and also for cutting

tools sharpening made of high speed steels.

Working speed,

RPM

Weight,

kg

Type 1

v lty

No e

!

WA

F30-F16

F230-F36

4-7

1; 2

O-S

J-S

АA; A

Characteristic

Grit

Hardness

Material

Structure

Accuracy class

Unbalance class