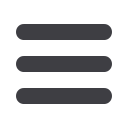

T,

mm

D,

mm

H,

mm

W

А

D

H

T

120

50

m

/

s

10

13

16

20

25

32

40

50

63

80

100

4

5

6

8

10

13

16

20

150

150

150

150

150

150

150

150

150

150

150

175

175

175

175

175

175

175

175

20; 32; 51

32; 51

12.7; 20; 32; 51

12.7; 20; 32; 51

32; 51

32

32

32; 51

51; 65

32; 51

32; 51

32

32

32

32

32

32

32

32; 51

0.390

0.500

0.640

0.800

0.970

1.240

1.540

1.890

2.280

3.060

3.830

0.220

0.280

0.320

0.430

0.530

0.690

0.850

1.070

28

20

20

16

12

8

8

8

4

4

4

60

50

38

28

22

20

14

12

6400

6400

6400

6400

6400

6400

6400

6400

6400

6400

6400

5450

5450

5450

5450

5450

5450

5450

5450

5450

5450

32

25

175

175

32

32

1.710

1.330

8

10

50

40

175

175

32; 76

32

2.640

2.140

6

6

5450

5450

4

200

32

0.280

19

4800

The plant receives the orders of wheels manufacturing with dimensions and characteristics

not indicated in the given table.

6

5

200

200

32; 76

32

0.430

0.350

26

16

4800

4800

For all types of grinding the details and constructions

of different kinds of steels and also for cutting

tools sharpening made of high speed steels.

Working speed,

RPM

Weight,

kg

Type 1

WA

F30-F16

F230-F36

4-7

1; 2

O-S

J-S

АA; A

Characteristic

Grit

Hardness

Material

Structure

Accuracy class

Unbalance class