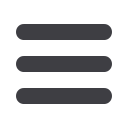

T,

mm

D,

mm

H,

mm

122

W

А

D

H

T

50

m

/

s

125

100

50

40

32

30

25

20

250

250

250

250

250

250

250

250

127

76; 127

76; 127

25.4; 32; 76; 127

32; 76; 127

76

25.4; 32; 51; 76; 127

32; 76

10.330

10.110

5.050

4.360

3.570

3.030

2.790

2.230

4

4

2

1

4

4

6

6

20

16

13

10

8

6

300

300

300

300

300

300

32; 76; 127

32; 76; 127

32; 76; 127

32; 76; 127

76; 127

32; 76; 127

3.160

2.450

2.170

1.670

1.290

0.910

12

9

7

3

3

4

9

300

127

1.175

7

3850

3850

3850

3850

3850

3850

3850

3850

3200

3200

3200

3200

3200

3200

3200

63

250

32; 76 ;127

6.370

2

3850

70

250

76

3850

6.864

2

80

250

32; 76; 127

8.760

2

3850

25

300

32; 76; 127

3.950

3

3200

3200

3200

32

30

300

300

32; 76; 127

127

5.060

4.000

2

3

The plant receives the orders of wheels manufacturing with dimensions and characteristics

not indicated in the given table.

80

300

76; 127

12.010

1

63

300

76; 127

9.580

1

3200

3200

3200

3200

3200

60

50

40

300

300

300

150

76; 127

32; 76; 127

7.220

7.500

6.320

2

2

1

For all types of grinding the details and constructions

of different kinds of steels and also for cutting

tools sharpening made of high speed steels.

Working speed,

RPM

Weight,

kg

Type 1

N v lty!

o e

WA

F30-F16

F230-F36

4-7

1; 2

O-S

J-S

АA; A

Characteristic

Grit

Hardness

Material

Structure

Accuracy class

Unbalance class