273

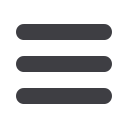

Installation of the Crucibles

Use only standard supports. Between crucible and support should

be separating material: paper, coke, alumina.

Around of an upper crucible edge it is necessary to create an even

gap. For this purpose it is possible to use cardboard or arboreal

chips. It is not allowed to use wedges made of fire proof material.

The burner axis should be in a bottom plane of a crucible.

A gap between crucible and a furnace cover should be insulated

by thermoinsulating material.

The burner should be established so that the flame does not flap

directly in a crucible and bent it on tangent.

For installation and extraction of crucibles tongs (claws) should be

used. Tongs should correspond to the shape of crucible and be

wrapped up with mild material.

In resistance ovens and induction furnaces air gap

between crucible's edge and oven's cover should

be sealed up by mixture on the ground of fireproof clay.

In induction furnaces space between crucible

and inductor is filled by insulating material.

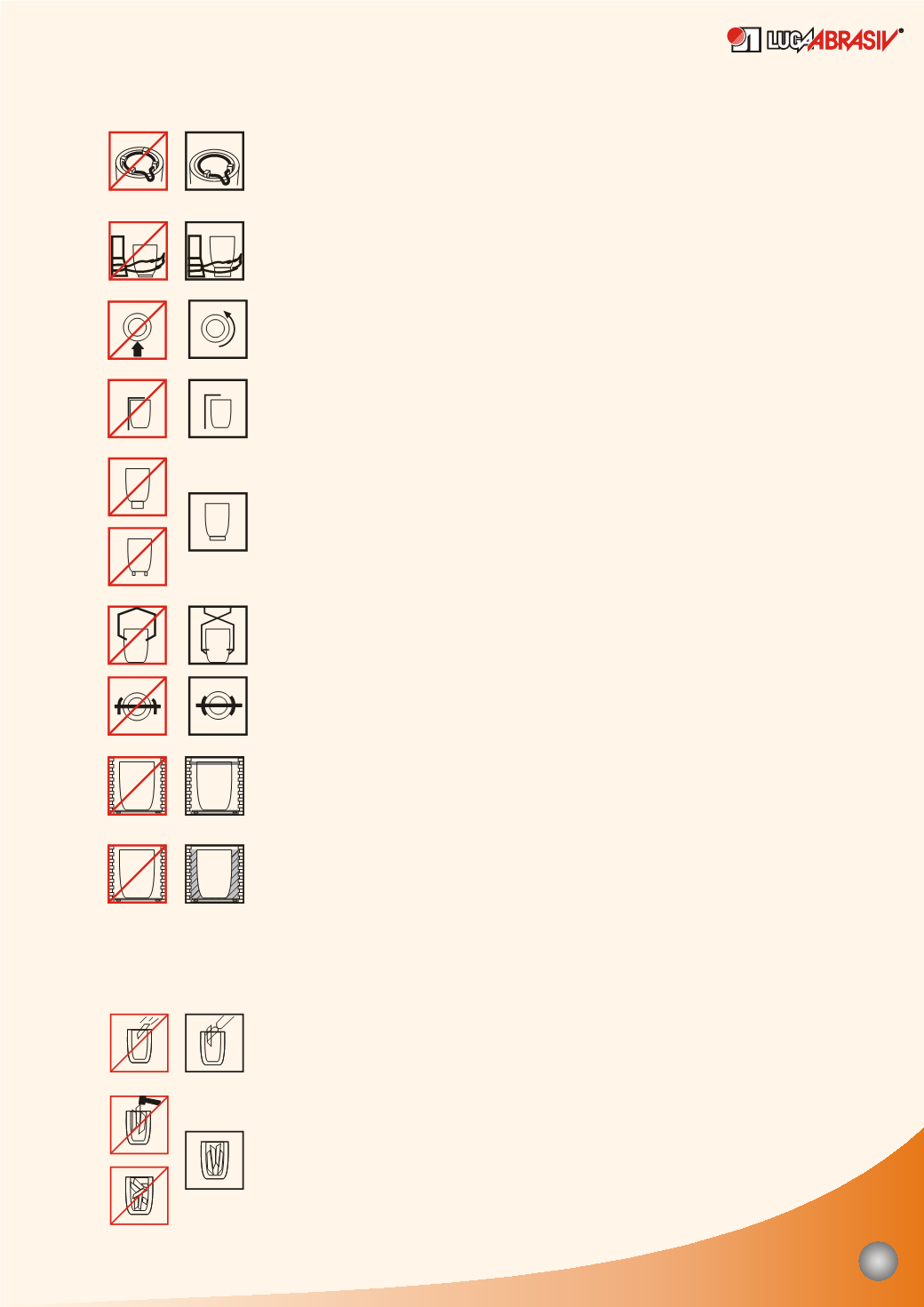

Loading of Metal

The metal is necessary to load in the previously warmed-over

crucible. The metal should be dry and heated a little.

The large pieces should be placed into crucible by grips,

avoiding their impacts with a crucible.

The ingots should be packed into a crucible upright excluding

jamming of separate pieces.