274

1h

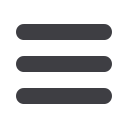

Conducting of Melting

It is necessary to change a level of melt in a crucible in order

to avoid fretting of crucible walls by drosses on a “mirror” of metal.

Enter the components only into molten metal.

Keep strictly to necessary quantity of chemical components for

modification of alloys.

It is forbidden categorically to warm up a crucible with metal

stiffened in it. The hole for emergency output of molten metal

in furnace should be closed.

Metal melting is necessary to conduct as soon as possible.

Don't leave empty crucible in the furnace between meltings.

Period between meltings should be minimal.

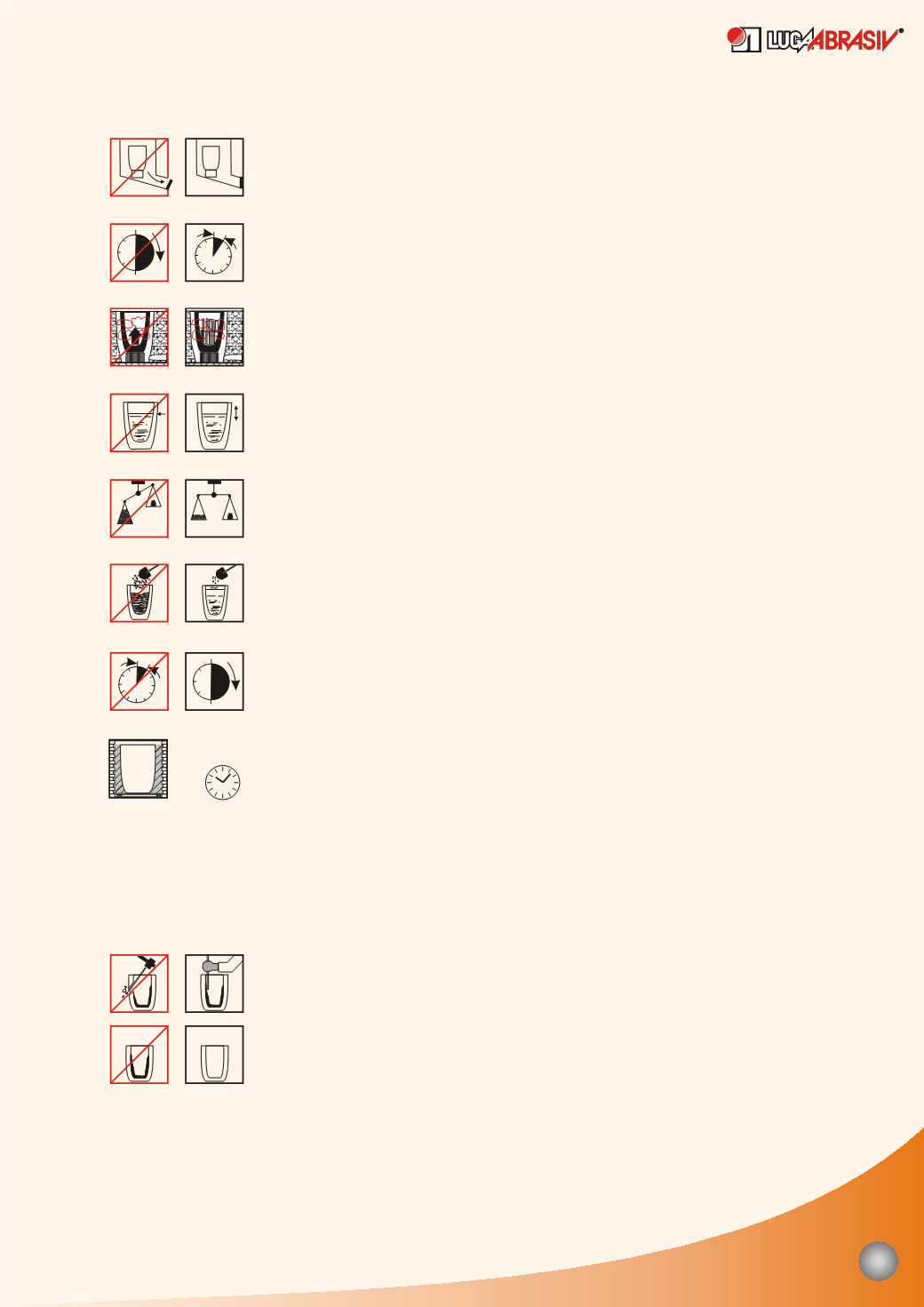

Cleaning of the Crucibles

At disconnection of the furnace it is necessary to remove the fluid

melt from crucible. At the end of melting process the

drosses should be accurately cleaned off from an internal surface

of hot crucible with the help of the metal scraper or blade.

1h

100°С

в час

In induction furnaces where heating and metal fusion occur at

the expense of currents proceeding in it, and the crucible is heated

from metal, it is recommended to increase gradually the energy to

provide uniform heating of the crucible. The optimum decision in

this case is the continuous operating mode.

After breaks in work (e.g. stops during weekends) it is necessary

to warm up slowly the empty crucibles in the furnace, regardless

of its type.