20

25

32

40

50

80

100

16

13

10

8

20

25

32

40

50

50

100

100

100

100

100

100

100

125

125

125

125

125

125

125

125

125

135

20; 32

20

20

20

20

20

20

12.7; 20; 32

20; 32

32

32

12.7; 20; 32; 60

20; 32

32; 51

32

32

51

0.298

0.370

0.474

0.592

0.753

1.346

1.507

0.390

0.290

0.230

0.180

0.490

0.590

0.720

0.900

1.150

1.220

32

24

16

16

16

8

8

32

40

64

64

24

16

16

8

8

3

6700

6700

6700

6700

6700

6700

6700

5350

5350

5350

5350

5350

5350

5350

5350

5350

4950

For all types of grinding the details and constructions

made of cast iron, non-ferrous metals, natural and

artificial stone, glass, porcelain, sharpening

of solid-alloy cutting tools,

.

for dressing of grinding

wheels

35m/

s

T,

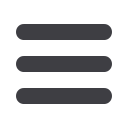

mm

D,

mm

H,

mm

D

H

T

16

13

100

100

20; 32

20

0.237

0.192

40

48

6700

6700

133

8

150

32

0.270

36

4500

63

80

20

0.593

4

8400

10

6

100

100

20; 32

32

0.149

0.085

64

96

6700

6700

100

80

20

0.913

4

8400

6

125

32

0.140

0.201

80

40

5350

6

150

32

4500

The plant receives the orders of wheels manufacturing with dimensions and characteristics

not indicated in the given table.

Type 1

Working speed,

RPM

Weight,

kg

C; GC

F230-F20

0-8

1; 2

H-R

АA; A

Characteristic

Grit

Hardness

Material

Structure

Accuracy class

Unbalance class