The plant receives the orders of wheels manufacturing with dimensions and characteristics

not indicated in the given table.

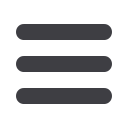

T,

mm

D,

mm

H,

mm

For all types of grinding the details and constructions

made of cast iron, non-ferrous metals, natural and

artificial stone, glass, porcelain, sharpening

of solid-alloy cutting tools,

.

for dressing of grinding

wheels

35m/

s

150

80

100

63

400

400

400

400

127; 203

1

1

1

1

50

40

32

20

450

450

450

450

127; 203

127; 203

127; 203

1

1

1

2

203

203

203

127

28.790

15.350

19.190

14.640

15.050

12.040

9.630

5.820

1700

1700

1700

1700

1500

1500

1500

1500

136

D

H

T

50

40

32

25

20

400

400

400

400

400

127; 203

76; 127; 203

127; 203

127; 203

127; 203

1

2

2

2

3

11.620

9.970

7.440

5.810

4.490

1700

1700

1700

1700

1700

16

400

5

127

3.600

1700

150

350

203

1

19.096

1950

25

20

13

100

300

350

350

350

76; 127

76; 127

127

127

4.710

3.770

2.160

11.930

3

4

5

1

2250

1950

1950

1950

40

32

350

350

76; 127; 203

76; 127

2

2

100

50

350

350

127; 203

76; 127; 203

1

2

7.540

6.030

17.180

9.140

1950

1950

1950

1950

25

450

2

203

6.114

1500

10

400

203

1700

6

1.842

16

350

127

2.576

4

1950

Type 1

N v lty!

o e

Working speed,

RPM

Weight,

kg

C; GC

F230-F20

0-8

1; 2

H-R

АA; A

Characteristic

Grit

Hardness

Material

Structure

Accuracy class

Unbalance class