16

13

10

8

6

20

25

32

40

175

175

175

175

175

175

175

175

175

32

32

32

32

32

32

32; 60

32

32

0.730

0.600

0.460

0.370

0.269

0.920

1.140

1.460

1.840

The plant receives the orders of wheels manufacturing with dimensions and characteristics

not indicated in the given table.

For all types of grinding the details and constructions

made of cast iron, non-ferrous metals, natural and

artificial stone, glass, porcelain, sharpening

of solid-alloy cutting tools,

.

for dressing of grinding

wheels

35

m

/

s

T,

mm

D,

mm

H,

mm

40

32

25

20

16

13

10

8

200

200

200

200

200

200

200

200

32; 76

32; 76

32; 76

16; 20; 32; 51; 76

32

32

32; 76

32

2.430

1.940

1.250

1.520

0.970

0.790

0.600

0.480

14

20

22

28

38

12

10

8

6

4

4

6

8

10

12

16

18

3810

3810

3810

3810

3810

3810

3810

3810

3810

3350

3350

3350

3350

3350

3350

3350

3350

134

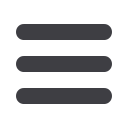

D

H

T

40

50

63

150

150

150

32

32

51

1.330

1.690

1.970

8

8

4

4500

4500

4500

13

10

16

150

150

150

32

20; 32

12.7; 32

0.430

0.340

0.560

20

28

20

4500

4500

4500

20

25

32

150

150

150

12.7; 20; 32

32; 76

32; 51

0.700

0.830

1.070

16

12

8

4500

4500

4500

Type 1

Working speed,

RPM

Weight,

kg

C; GC

F230-F20

0-8

1; 2

H-R

АA; A

Characteristic

Grit

Hardness

Material

Structure

Accuracy class

Unbalance class